INTRODUCTION

Hoang Kim Precision was established in 2015 with an initial investment of 150,000 USD, operating in the field of precision mechanical processing and focusing on supplying products to Japanese companies based in Vietnam.

With 3 criteria: “Best quality. Competitive price. Delivery on time” , up to now, Hoang Kim Precision has owned two manufacturing factories with a total number of employees of more than 70 people, the main production factory with an area of up to 2000 square meters is invested in an electrical system. Solar energy, green energy source with capacity up to 500KWH in the City. Thu Duc and a secondary production factory with an area of 500 square meters in Binh Chanh.

BUSINESS AREAS

With main areas of activity:

+ Precision mechanical processing (electronics, semiconductor, telecommunications, aviation, car industries…)

+ Machine manufacturing (electronics, food industry).

+ Conveyors, vibrating trays, tables and shelves.

FEATURED PRODUCTS/ SERVICES

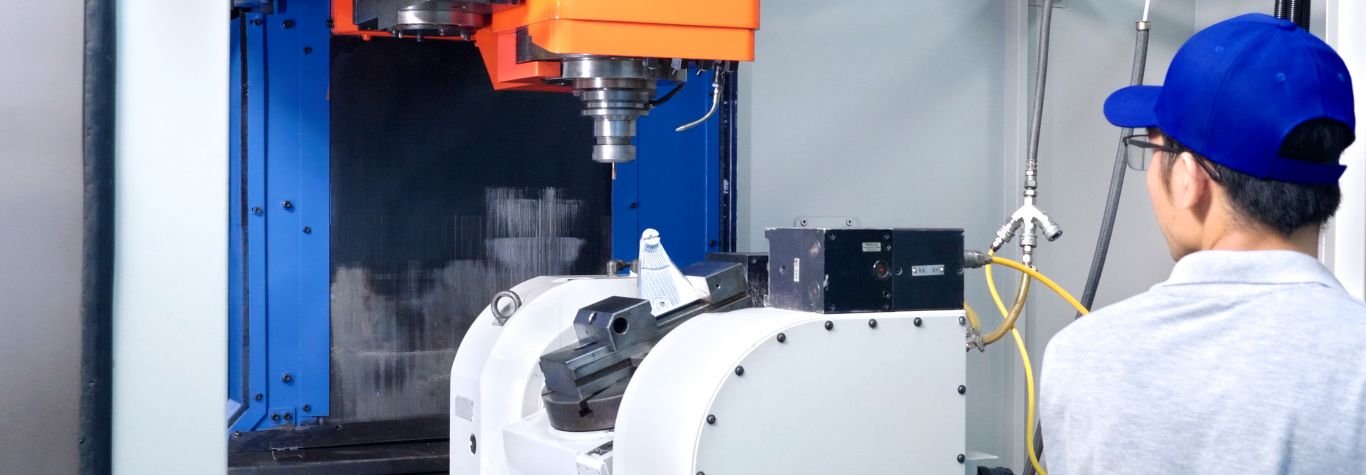

CNC machinery serves production needs (Milling, turning, wire cutting, etc.)

Hoang Kim Precision is proud to be the leading unit in providing advanced CNC machinery to serve the production needs of domestic and foreign businesses. With a variety of types and outstanding features, Hoang Kim Precision’s CNC machine lines include CNC milling machines, CNC lathes, wire cutting machines and electric shooting machines, fully meeting the strict requirements in the industry. manufacturing industry.

1. CNC milling machine

- High precision: Hoang Kim Precision’s CNC milling machines are designed with high precision, helping to process complex details with absolute precision.

- Diversity of sizes and capacities: Suitable for many different types of products and processing requirements, from small details to large parts.

- Modern control system: Equipped with an advanced CNC control system, easy to program and operate.

2. CNC lathe

- Outstanding performance: Hoang Kim Precision’s CNC lathes deliver high machining efficiency, helping to save time and production costs.

- Diverse machining capabilities: Can process different types of materials such as metals, plastics, and alloys.

- High durability: Solid and durable design, ensuring long-term stable operation.

3. CNC wire cutting machine

- Precise cutting: Hoang Kim Precision’s CNC wire cutting machine allows cutting parts with high precision and smooth cutting surface.

- Wide application: Suitable for many industries such as electronics, mechanics, and mold manufacturing.

- Save materials: Minimize the amount of material wasted during the cutting process.

4. CNC electric shooting machine

- Small detail machining: Especially suitable for machining small and complex parts with high precision.

- Fast machining speed: Increase production productivity with fast and efficient machining speed.

- Easy programming: CNC control system makes it easy to program and adjust machining parameters.

Why should you choose CNC machinery from Hoang Kim Precision?

- Guaranteed quality: Hoang Kim Precision is committed to providing high quality CNC machinery products, regularly inspected and maintained.

- Good after-sales service: Technical support and long-term warranty, ensuring customers always feel secure when using the product.

- Competitive prices: Providing products at reasonable prices, meeting all business budget needs.

- Professional team: A team of experienced and highly specialized technicians, always ready to support customers.

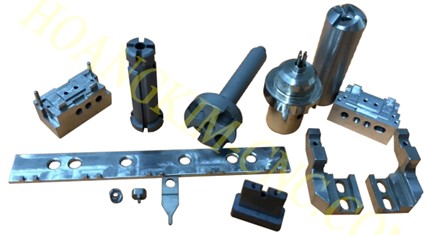

Precision mechanical processing (electronics, semiconductor, telecommunications, aviation, car industries…)

Hoang Kim Precision is proud to be a pioneer in providing precision mechanical processing services, serving the electronics, semiconductor, telecommunications, aviation and car industries. With more than many years of experience in the industry, Hoang Kim Precision is committed to providing high quality products and services, meeting all strict requirements of customers.

Precision Mechanical Machining Services:

- Processing for the electronics industry

- Small and complex parts: Ensures high precision for small and complex electronic parts, helping to improve product performance and longevity.

- Diverse materials: Machining on a variety of materials such as aluminum, copper, stainless steel, and other alloys, suitable to the requirements of the electronics industry.

- Processing for the semiconductor industry

- High precision: Manufacture semiconductor components with absolute precision, ensuring optimal performance of semiconductor devices.

- Modern technology: Using advanced CNC technology to process complex details, meeting the strict needs of the semiconductor industry.

- Processing for the telecommunications industry

- Quality telecommunications components: Machining high quality telecommunications parts and components, helping to optimize transmission performance and minimize problems.

- Meet international standards: Ensure processed products meet international standards, in accordance with the strict technical requirements of the telecommunications industry.

- Processing for the aviation industry

- Safety and reliability: Producing mechanical parts with high durability and precision, ensuring safety and reliability for aviation equipment.

- High-quality materials: Using high-quality materials such as titanium, aluminum alloy, and specialized steels to ensure product quality.

- Processing for the car industry

- Precision car components: Machining car components and parts with high precision, helping to improve vehicle performance and longevity.

- Advanced production process: Applying advanced production processes, ensuring high quality products and quick delivery time.

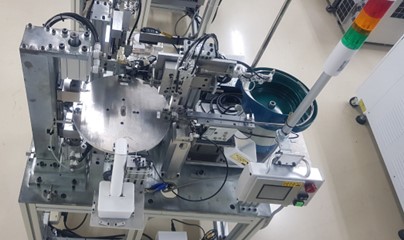

Machine manufacturing (electronics, food industry)

Hoang Kim Precision is proud to provide professional machine manufacturing services, serving the electronics and food industries. With a team of experienced engineers and modern technology, Hoang Kim Precision is committed to providing optimal machine manufacturing solutions, helping customers improve production efficiency and quality.

Machine Manufacturing Services:

- Manufacturing Machines for the Electronics Industry

- Automated production equipment: Manufacturing automated machines for electronic components production lines, helping to increase productivity and reduce errors.

- Testing and measuring machines: Manufactures precision testing and measuring equipment, ensuring the quality and reliability of electronic products.

- Welding and assembly equipment: Manufacturing automatic welding and assembly machines, helping to optimize production processes and ensure high accuracy.

- Manufacturing Machines for the Food Industry

- Packaging machines: Providing automatic packaging machine solutions, suitable for many different types of food products, helping to preserve products better and extend shelf life.

- Processing machines: Manufacture of food processing equipment such as choppers, grinders, and mixers, ensuring fast and efficient processing processes.

- Quality testing equipment: Production of food quality testing equipment, helping to ensure food safety and hygiene and compliance with international standards.

Benefits of Choosing Hoang Kim Precision’s Machine Manufacturing Service:

- Outstanding quality: Using premium materials and components, ensuring machine durability and performance.

- Professional team: A team of experienced engineers and technicians, always ready to advise and support customers.

- Advanced technology: Applying modern manufacturing technologies, ensuring high product accuracy and quick delivery time.

- Customized solutions: Providing machine manufacturing solutions according to customers’ specific requirements, meeting all specific production needs.

Working process:

- Consulting and survey: Hoang Kim Precision’s team of experts will work closely with customers to understand specific needs and requirements.

- Design and planning: Hoang Kim Precision will conduct detailed design and production planning, ensuring technical standards and delivery times are met.

- Manufacturing and assembly: The manufacturing and assembly process is carried out with strict supervision, ensuring the quality of output products.

- Inspection and acceptance: All machines are inspected and accepted before being handed over to customers, ensuring stable and efficient operation.

Contact Hoang Kim Precision:

Hoang Kim Precision is committed to providing high quality machine manufacturing solutions, helping customers improve productivity and production efficiency. Please contact Hoang Kim Precision for advice and to experience professional service.

CONTACT INFORMATION

Booth 466 – VIMF Binh Duong 2024

Tel: +84 898 788 040 – Ms Huong Giang

Website: www.omg-expo.com

Email: giang@vimf.vn

EN

EN VI

VI