INTRODUCTION

Bay Union was founded in 1987. We have focused on producing vitrified bonded grinding wheels for many years. Bay Union has advanced vitrified bonds and special self-developed equipment, so we can supply high quality grinding wheels in a very fast and steady way.

BUSINESS AREAS

Semiconductors, bearings, screws, linear guides, gears, hydraulic components, machine tool spindles, sleeves, and optical molds

PRODUCTS

1. Linear Guideway Grinding Wheel

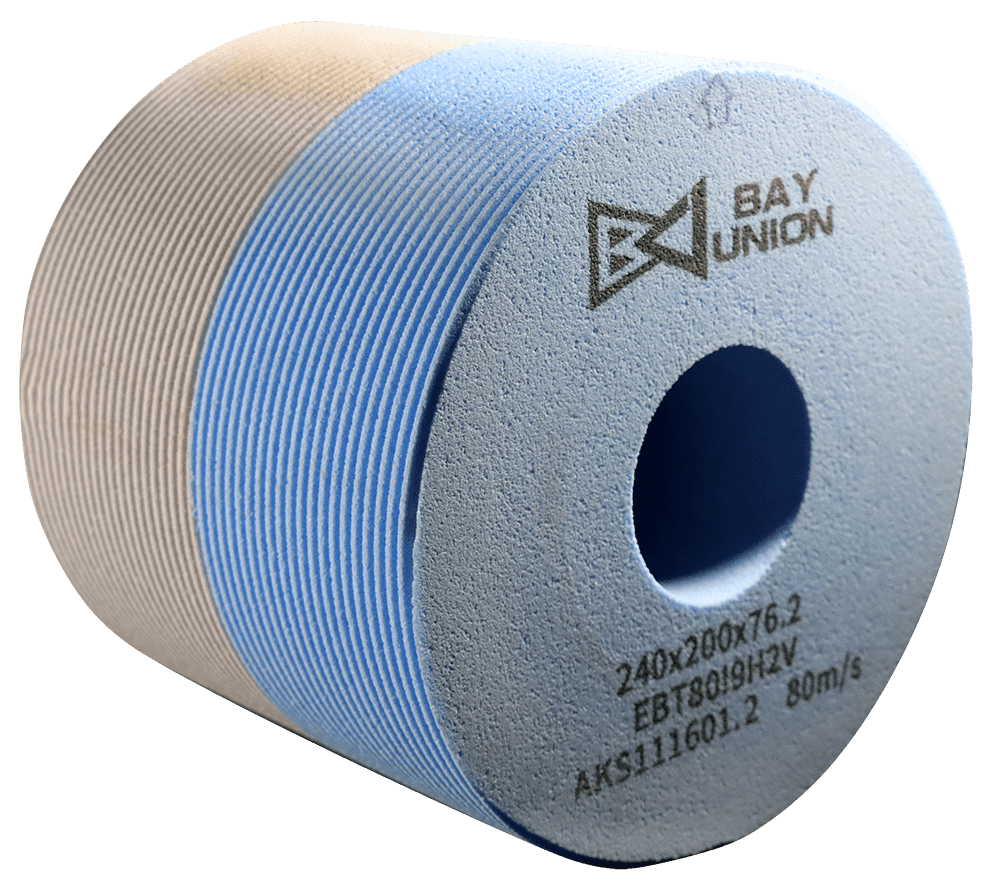

EBT

Using strip-shaped TG abrasive combined with low-temperature sintering provides high removal capability for high-carbon steel and alloy steel sliders/rails, offering either deep-cut slow-advance or shallow-cut ultra-fast-advance capabilities. (The dressing parameters of the diamond dressing wheel must be adjusted accordingly.)

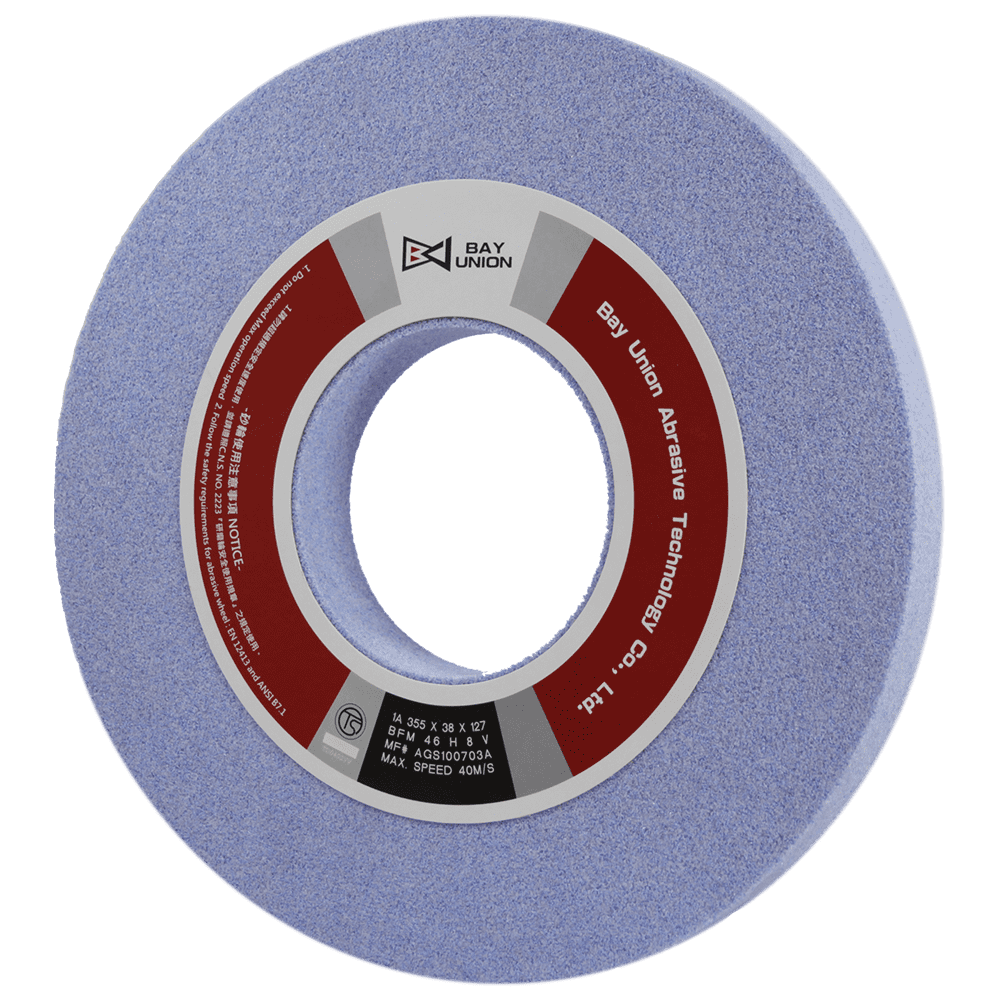

BF/BFM

High self-sharpening SG combined with low-temperature sintering has the characteristics of long life of microcrystals, reduces the amount of sand repair, and has stable and efficient grinding characteristics; BFM is used for applications that require higher surface roughness.

CK/CKL

Special sharp single-crystal abrasive, widely used for grinding stainless steel 400 series sliders/rails. It offers superior chip breaking performance compared to general alumina WA/PA formulations, reducing wheel clogging and burning issues. Compared to silicon carbide GC formulations, it boasts better shape retention, significantly reducing waste during finishing.

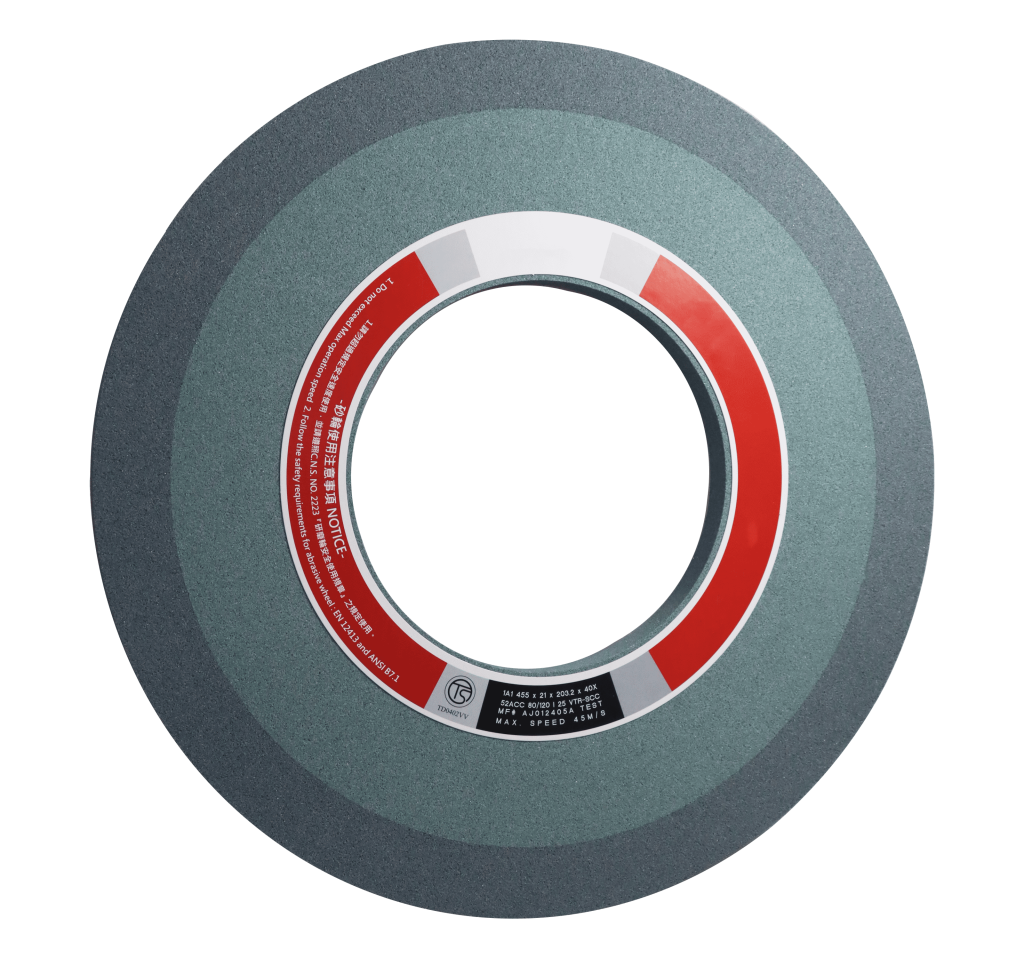

2. Gear Grinding Wheel

Bay Union utilizes high-quality microcrystalline abrasives to design the EBT/BFW/GFW series of continuous generation grinding wheels. These wheels are capable of overcoming challenges associated with surface hardening treatments on gears. They enhance gear grinding efficiency, reduce wheel wear, and extend tool life. The stability of gear profiles achieved with these wheels results in significant improvements in transmission performance, including reduced friction losses, higher transmission efficiency, and longer service life.

3. Vitrified bonded CBN Wheel

CBN grinding wheel is a type of grinding wheel that uses Cubic Boron Nitride as abrasive. Its features are as follows

High hardness

CBN grinding wheel has a much higher hardness than conventional grinding wheels, so it can more effectively remove materials with high hardness, such as high-speed steel, alloy steel, and bearing steel.

High thermal stability

CBN grinding wheel has high thermal stability, and can be used for a long time in high-temperature environments without losing its strength, making it an ideal grinding wheel for processing high-hardness materials.

High precision

CBN grinding wheel can achieve high-precision grinding, with good surface roughness and high profile quality of the workpiece.

Long life time

Due to the high hardness of CBN grinding wheel, its service life is long and can be several times that of conventional grinding wheels.

BAY UNION can highly customize CBN grinding wheels to meet your grinding needs, greatly improving grinding efficiency and extending the life of the grinding wheel.

CONTACT

VIMF – VIETNAM INDUSTRIAL & MANUFACTURING FAIR

Event Date: 17-19/06/2026

Location: WTC International Exhibition Center, Binh Duong

Number of booths: 173

If you need any further information, please feel free to contact:

Hương Giang – Dendy (Ms)

Onsite Operation Manager

OMG Events Management CO., LTD

Mobile/Zalo: (+84) 898 788 040

Website: omg-expo.com || vietnamindustrialfiesta.com

Address: 1014 Pham Van Dong Street, Hiep Binh Ward, HCMC

EN

EN VI

VI