INTRODUCTION

HUST Vietnam Technical Equipment Joint Stock Company (HUST Vietnam JSC) has the mission of being a supplier of scientific, experimental & measurement equipment, complete solutions for production and product quality inspection in fields of electricity – electronics, motor vehicles, energy, metallurgy, …

HUST Vietnam’s technical team is constantly researching and finding the most advanced and suitable solutions for customers. Currently, we are focusing on the following product lines: DELO industrial adhesives, Test cabinets. environment, product reliability testing equipment, …

BUSINESS AREAS

Product:

- DELO adhesives and industrial chemicals

- Environmental testing cabinet

- Analytical equipment

- Precision measuring equipment

- Non-destructive testing equipment

- Reliability testing equipment

- Sample preparation equipment

- Battery test equipment (Battery test equipment)

Technical services:

- Equipment installation & user manual

- Maintenance

- Calibrate periodically

FEATURED PRODUCTS

DELO industrial adhesive

DELO adhesive is a versatile industrial adhesive, compatible with both UV and moisture curing methods, with medium viscosity. The glue’s composition includes modified acrylate, a one-component glue that does not contain solvents. With a high elongation coefficient, it ensures uniform elasticity. The operating temperature of the glue is from -40°C to 150°C, suitable for each specific application. DELO adhesive meets RoHS 2015/863/EU standards.

Some applications of DELO industrial adhesives:

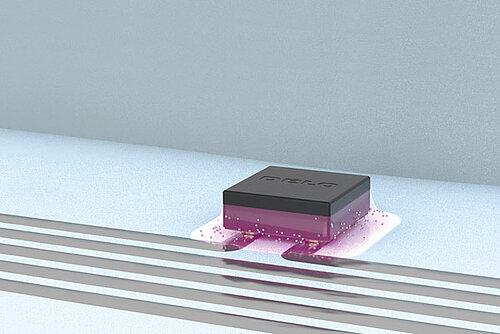

Adhesive in RFID card chip

From product packaging and ski tags to RFID transponders: Reliable radio tag functionality depends on the connection between the semiconductor chip and the antenna. Semiconductor adhesives play an important functional role. They attach small chips to the antenna and in most cases they require a conductive adhesive.

DELO is the world’s leading manufacturer of RFID adhesives. Approximately 80% of RFID tags globally contain a drop of DELO adhesive. Depending on the process, anisotropic conductive (ACA) or non-conductive (NCA) adhesives are used to bond the chips.

Developed specifically for LF, HF and UHF antennas, DELO’s epoxy resins meet high requirements for durability, temperature and humidity resistance and ensure a fast adhesive process. Tag manufacturers are aiming for an output of 100,000 RFID labels per hour.

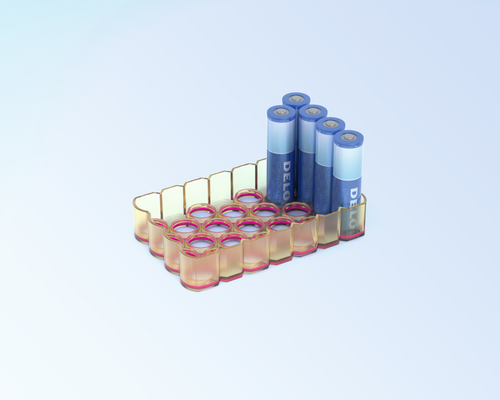

Fast curing DELO glue for electric vehicle battery bonding

For high-volume applications such as bonding cylindrical batteries to storage trays, battery manufacturers benefit from DELO’s extensive portfolio of fast-curing adhesives. These UV-cured acrylate bonds cure in seconds and make time-consuming batch production a thing of the past. In addition to built-in fire resistance and excellent adhesion to fire-resistant plastics, these adhesives also provide built-in protection against vibration, enhancing battery pack durability.

VISIONTEC corrosion test salt mist chamber

VISIONTEC salt spray cabinet (salt spray machine) is a salt spray corrosion testing device with a small size and is easy to move. Spray booth sizes range from 600 x 450 x 450mm to 900 x 600 x 600mm, suitable for testing products or small details, saving investment costs and equipment space.

Application

– Used in the automobile and motorcycle manufacturing industry and aerospace industry.

– Check surface coating, plating, and paint materials

– Military material production industry.

– Spring industry, bolts and screws,

Feature

– VISIONTEC salt mist spray cabinet is designed based on advanced monoblock technology, the spray chamber of VISIONTEC salt mist spray cabinet is designed to ensure convenience for machine operation and maintenance. The control panel on the VISIONTEC salt mist spray cabinet is located in a workspace to ensure the most convenience for the user.

– The entire frame of the spray booth is made of anti-corrosion materials such as SUS 304 stainless steel and PVC or PP plastic, they are machined with smooth profiles and surfaces to ensure durability and compact footprint. . The roof of the spray booth is made of transparent plastic so that users can observe the spraying process while the machine is operating.

– Sample racks and support bars are all made of heat-resistant PVC or PP, highly corrosion-resistant, ensuring rigidity when placing samples.

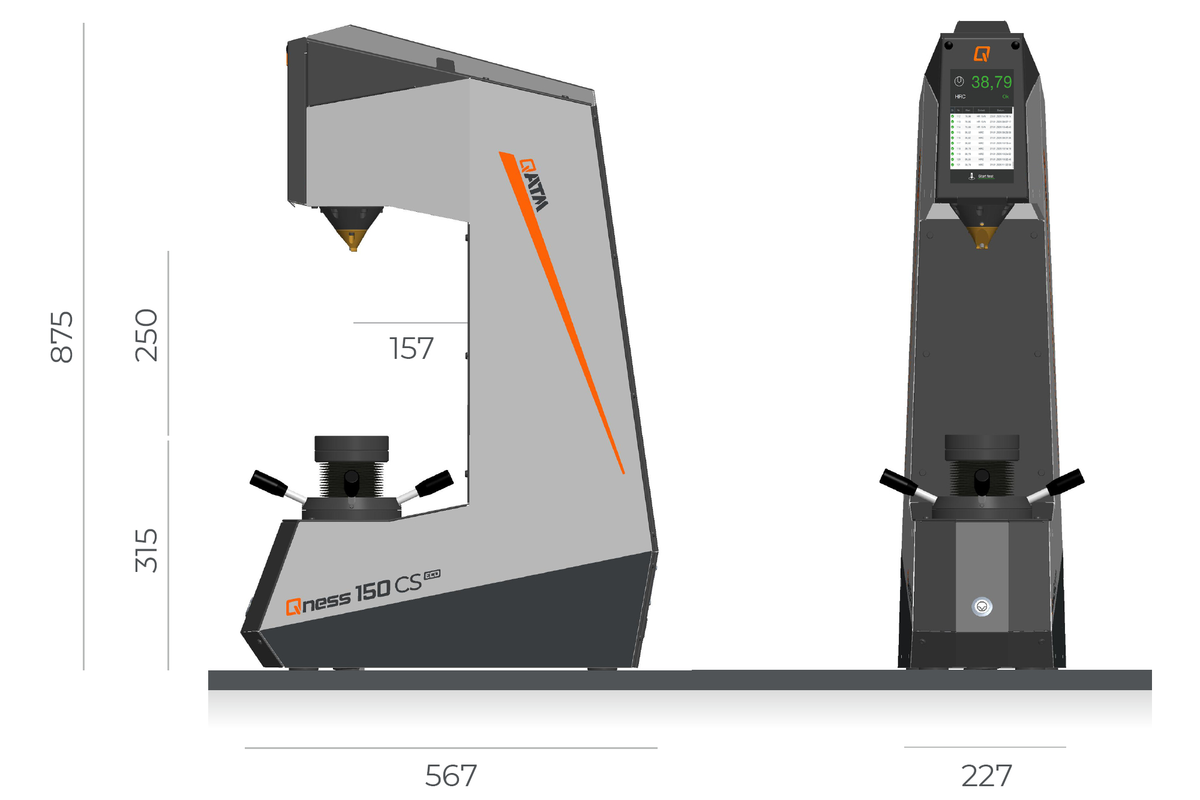

Rockwell Qness 150 CS ECO hardness tester tested for reliability

The “C” shaped chassis features a robust and compact design (The “S” stands for compact) that gives the Qness 150 CS ECO its name. Part of the QATM ECO product line, this Rockwell hardness tester combines high-quality workmanship with maximum simplicity of operation.

The machine design with a fixed test head and up/down moving spindle has been the standard in hardness testing for decades and is suitable for small to medium sized test pieces in application in virtually any work environment. job.

QATM configures the Qness 150 CS ECO with an extremely accurate, direct HEIDENHAIN depth measurement system, precisely positioned on the axis of the indenter. This ignores measurement inaccuracies caused by distortions in the system. Another unparalleled benefit: Indentation depth can be measured directly – and absolutely, and can be easily calibrated to the latest Rockwell standards ASTM E 18:2020 and DIN EN ISO 6508.

Modern features provided as standard:

- Controlled force application (1kg to 250kg)

- Direct depth measurement system (0.05μm resolution)

- Sturdy welded steel frame

- Operates on a 7” color touch screen with Qpix TE software

- Transmits digital data via USB interface

- Fully automatic testing cycle: Application of electronic force and closed-loop control

Featured

- The display is extremely large and clear

- Evaluate the green and red OK/NG results according to the set tolerance levels

- List of test results for 999 values

- Statistics overview (min/max/range/cp/cpk/average)

- Unit conversion

- Surface correction

- Changing the testing method is simple

- Choose from many languages

- Can set many levels of passwords depending on requirements

CONTACT INFORMATION

Booth B85 – VIMF Binh Duong 2024

Tel: +84 898 788 040 – Ms Huong Giang

Website: www.omg-expo.com

Email: giang@vimf.vn

EN

EN VI

VI