INTRODUCTION

Established in 1976, Jo LONG has been centered on repairing tools for automobiles/motorcycles and lubrication/maintenance equipment. Over the past 30 years or even longer, it is thanks to Jolong’s superior quality and preferential price that we have been loved and held in high esteem in the industry involved.

BUSINESS AREAS

Lubrication equipment and car maintenance equipment

Business nature: Manufacturer/Trader

FEATURED PRODUCTS

Air Operated Grease Pump

Designed to streamline the process of transferring grease from the original barrel to various applications, this pump offers a range of features and benefits to meet your lubrication needs.

Features:

- Dual System Design: Our pump features a unique system where pump movement and oil suction are separated, preventing contamination of the grease during operation. This ensures the integrity and quality of the grease, maintaining optimal performance for your machinery.

- Versatile Application: Ideal for a wide range of industries and settings, including workshops, service stations, fleet maintenance, mining, agriculture, construction, and more. Wherever grease lubrication is needed, Jolong’s pump delivers consistent and reliable performance.

- Quiet Operation: Experience smooth and seamless greasing without the disruptive noise often associated with traditional grease pumps. Jolong‘s air-operated design ensures low noise levels, providing a comfortable working environment.

- Durable Construction: Crafted from high-quality aluminum alloy through forging, Jolong’s pump offers durability and longevity, even in demanding industrial environments.

Usage:

- Compatibility: Our pump is compatible with general 00# to 2# grease, making it suitable for a wide range of lubrication applications.

- Enhanced Performance: Equipped with an FP101 follower plate, Jolong’s pump can handle higher viscosity grease or operate in colder environments with ease, ensuring consistent grease distribution.

Experience the efficiency and reliability of Jolong’s Air Operated Grease Pump for your lubrication needs. Whether you’re maintaining machinery in a workshop or servicing vehicles in a fleet, Jolong’s pump is designed to deliver consistent performance and hassle-free operation.

Air Operated Oil Pump

Our Air Operated Grease Pump is designed to streamline the process of lubrication in various industrial settings. Here’s what sets Jolong’s pump apart:

Features:

- Dual System Design: Our pump incorporates a unique dual system where pump movement and oil suction are separated, preventing any contamination of the grease. This ensures that your grease remains pure and free from impurities, maintaining optimal performance.

- Versatile Application: Widely used across a range of industries including workshops, service stations, fleet maintenance, mining, agriculture, armed forces, construction, trains, and more. Wherever grease lubrication is needed, Jolong’s pump delivers reliable performance.

- Pneumatic Operation: Utilizing a pneumatic pump, Jolong’s grease pump does not require electric power, making it suitable for use in environments with flammable substances such as gas stations and car maintenance plants. This ensures safety and efficiency in operation.

- Durable Construction: Crafted from high-quality aluminum alloy through forging, Jolong’s pump offers durability and longevity, capable of withstanding the rigors of industrial applications.

Usage:

- Pressure Ratio: With a pressure ratio of 16:1, Jolong’s pump is suitable for pumping 140# to 200# gear oil or general non-corrosive solvent, providing versatility in lubrication tasks.

- Optional Accessories: For added convenience, we offer optional accessories such as flow meters (Model: M101, M201) to measure oil volume accurately and hose reels (Model: RE020) for pumping oil over long distances. These accessories enhance the functionality of Jolong’s pump and cater to specific lubrication needs.

Experience the efficiency and reliability of Jolong’s Air Operated Grease Pump for your lubrication requirements. Whether you’re maintaining machinery, servicing vehicles, or handling industrial equipment, Jolong’s pump is designed to deliver consistent performance and ease of use.

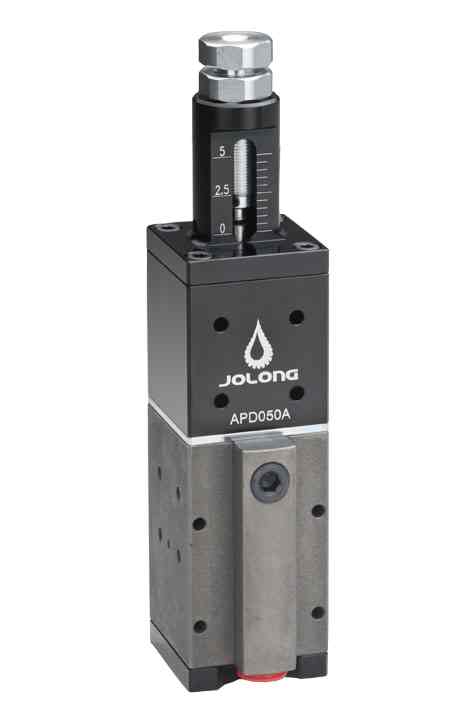

Grease/Oil Dosing Valve

Our Grease/Oil Dosing Valve is an essential component designed for precise and controlled dispensing of grease or oil in factory automation equipment. Here’s what you need to know about our dosing valve:

- Precise Dosing: Our dosing valve enables accurate and quantitative output of grease or oil, ensuring precise lubrication in automated manufacturing processes. This level of control is crucial for maintaining optimal equipment performance and prolonging the lifespan of machinery components.

- Versatile Application: The dosing valve is suitable for a wide range of factory automation equipment, including assembly lines, robotic systems, conveyor belts, and more. Wherever lubrication is required, our dosing valve provides reliable and consistent dispensing, contributing to seamless production operations.

- Enhanced Efficiency: By automating the lubrication process with our dosing valve, manufacturers can achieve higher efficiency and productivity in their operations. The valve eliminates the need for manual lubrication, reducing downtime and labor costs associated with traditional lubrication methods.

- Durable Construction: Crafted from high-quality materials, our dosing valve ensures durability and reliability even in demanding industrial environments. Its robust construction withstands the rigors of continuous operation, offering long-term performance and minimal maintenance requirements.

Experience the precision and efficiency of our Grease/Oil Dosing Valve for your factory automation needs. Whether you’re optimizing production lines, improving equipment reliability, or enhancing overall efficiency, our dosing valve is designed to meet your lubrication requirements with precision and reliability.

CONTACT INFORMATION

Taiwan Pavilion – Booth 115 – VIMF Binh Duong 2024

Tel: +84 898 788 040 – Ms Huong Giang

Website: www.omg-expo.com

Email: giang@vimf.vn

EN

EN VI

VI