Founded in 1983, we are a world leader of the manufacture of high-quality automatic machines and equipment for polishing, grinding, deburring and satin finishing of metal and other materials with and without system robot integration.

Currently present in key strategic markets in more than 38 countries thanks to the company’s internationalization and solid trade network. We continuously provide the highest level of technology with international coverage. Customer satisfaction is our main goal.

- 1985 World’s first CNC polishing machine with 5 programmable axes.

- 1986 World’s first CNC polishing machine with 6 programmable axes.

- 1989 World’s first rotary CNC grinder with six grinding units and a total of 30 programmable axes.

- 1994 First grinding cell with industrial robot.

- 1999 The world’s first DUPLO CNC polishing machine.

- The first 2000 series of multi-robots for grinding and polishing. Five robots line up.

- 2010 The world’s first TRIPLO CNC polishing machine.

With main products

1/ PROCESS AUTOMATION

Specialists in automation solutions for surface finishing.

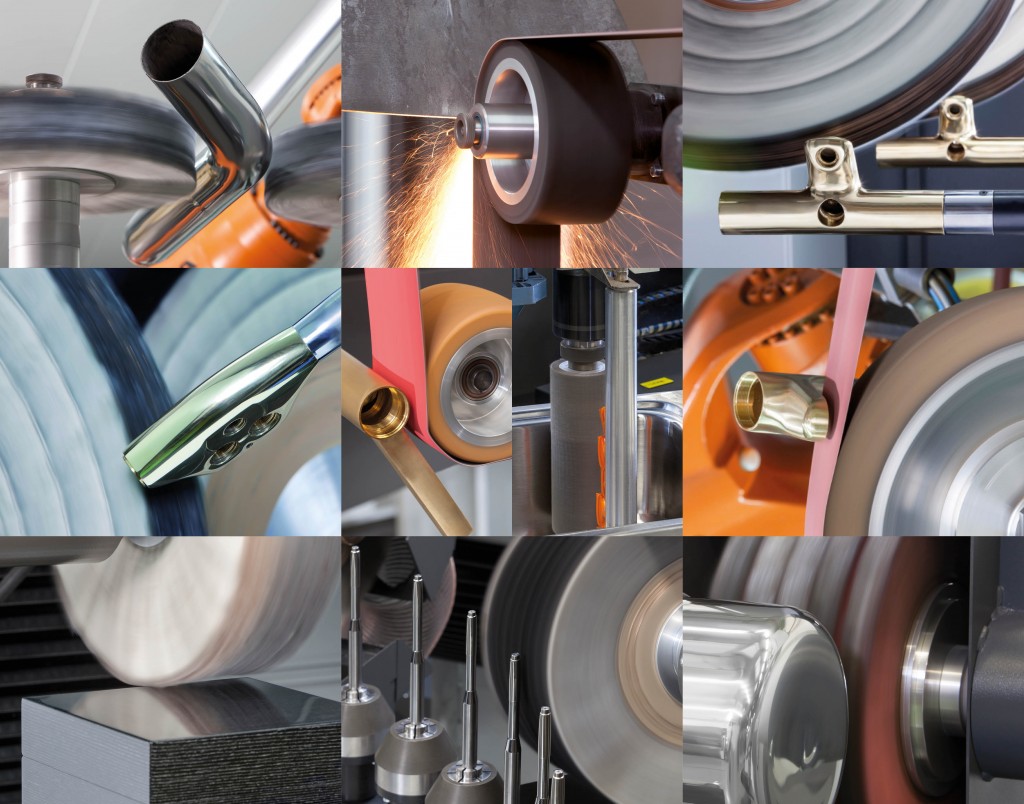

Grinding · Polished · Satin · Deburring · Machining

Development and technical application of innovative grinding and polishing processes of various materials that require high dimensional and surface roughness parameters. The previous process tests guarantee the viability of the project and offer an optimal balance between productivity and profitability of our equipment.

2/ APPLICATION SECTORS

- Aluminium extrusions

- Aluminium wheels

- Automotive components

- Autoclaves

- Bathroom & bath towel radiators

- Builder’s Hardware – Door Handles & Plates

- Bicycle parts

- Cosmetics – Aluminium caps

- Cookware – Pots and Pans

- …..

3/ APPLICATION SECTORS

With the experience accumulated over the years, MEPSA apply the latest technologies to make operations easier and improve the efficiency of our machines.

INDUSTRY 4.0 We provide Industry 4.0 solutions for data analysis to improve productivity and efficiency.

I+D The philosophy of continuous improvement guarantees a high standard of quality and innovation in the development of new applications and processes.

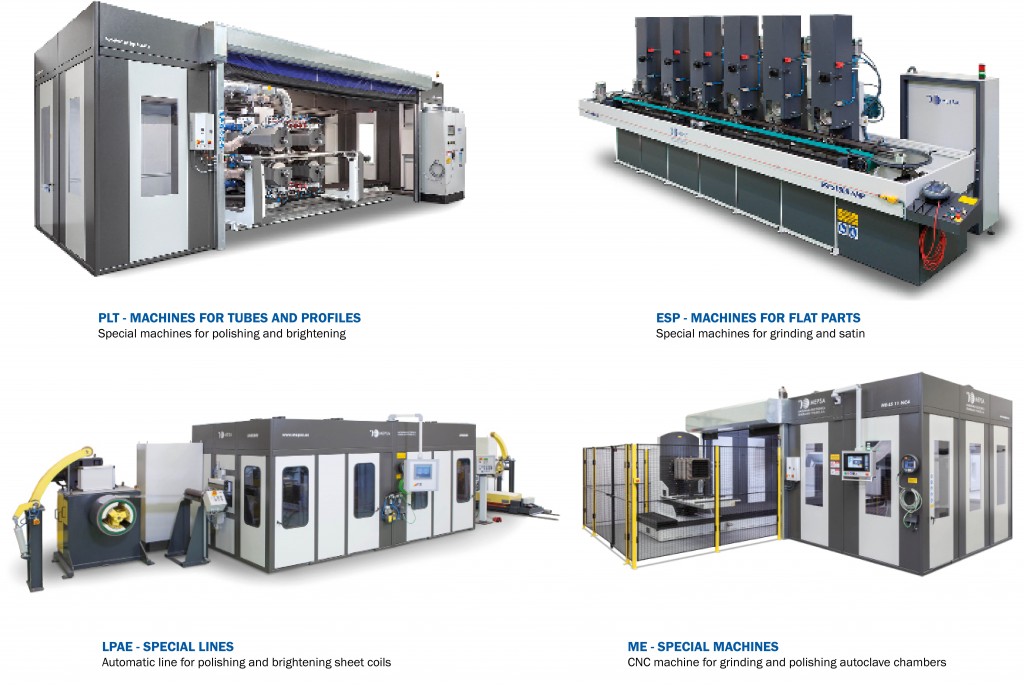

4/ CNC

Pioneers in the application of CNC numeric controls in grinding and polishing machines. (1985)

NUMERIC CONTROL Linear machines with 5 or 6 programmable CNC axes. Rotary machines with up to 8 polishing units with a total of 48 programmable CNC axes. Special grinding and polishing lines with up to 70 programmable CNC axes. Application of multi-unit systems. (1989)

MEPSA SMARTPOLIP® Exclusive Teach System programming software, based on the creation of grinding or polishing programs by automatic movement emulation. Intuitive and very easy to program, with a graphic display of the options to be executed. No specific training is required from the user.

MULTIPURPOSE WORK The system applied to rotary machines offers the possibility of simultaneously processing several different parts models in the same work cycle.

HIGH PRODUCTION We are specialized in creating high-production machinery.

MRI NC DUPLO Simultaneous polishing and brightening process of two equal parts at each workstation on a rotary machine. (1999)

MRI NC TRIPLO Simultaneous polishing and brightening process of three equal parts at each workstation on a rotary machine. (2010)

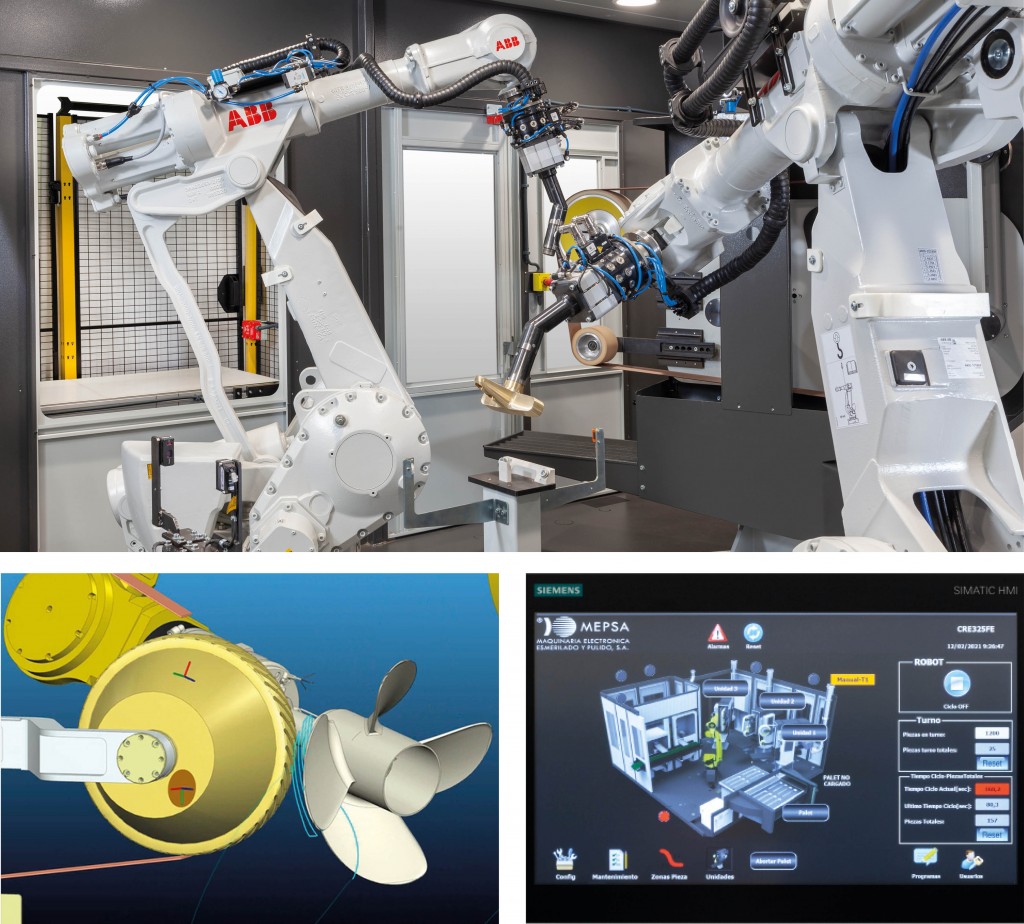

5/ ROBOTIC CELLS

MEPSA offer solutions with maximum flexibility and automation for machining, deburring, grinding, polishing processes, etc. (1994)

SPECIAL MULTIROBOT LINES

Inline multi-robot applications combining different finishing processes. Grinding, grinding and polishing, deburring with machining and grinding operations, among other options. (2000)

OFFLINE ROBOT PROGRAMMING

Offline simulation and programming software for robot trajectories to generate part-programs in the grinding and polishing processes. Virtual 3D programming from an external computer, without the need to interrupt cell production.

HMI-EASY AND INTUITIVE INTERFACE

Development of a new concept to increase performance and simplify the management, control, and regulation of multiple functions and machine parameters. Intuitive software with graphic identification of the different menus included.

VIMF 2023 – The 15th International Specialized Exhibition on Machinery, Equipment, Materials Tools, Applied Engineering Technology for the Manufacturing Industry, Mechanical Engineering and Supporting Industries for the 16th time in Vietnam. VIMF 2023 will bring practical insights into the latest strategies, tools, trends in the fields of machine tools and metalworking, measuring and measuring tools, 3D design printing, metalworking sheet types, manufacturing software, tools and tooling systems, contract manufacturing, welding and coating to enhance and maximize productivity and operational efficiency in manufacturing and supporting industries

————————————–

Our solution consultants will be present at BOOTH 54 of VIMF Binh Duong International Exhibition 2023. Come and connect with us!

VIMF’s organizer for instant connection:

Phone: +84 898 788 040 – Ms Huong Giang

Address: 3rd floor, St. Moritz, 1014 Pham Van Dong, Hiep Binh Chanh, Thu Duc, HCMC

Website: www.omg-expo.com

Email: giang@vimf.vn

EN

EN VI

VI