INTRODUCTION

Roeders Vietnam Co., Ltd. belongs to the same group as the Roeders GmbH in Germany, which has a company history of more than 200 years and is well known for its high tech High Speed Cutting machines, blow molds for PET bottles and pewter. Roeders Vietnam started in 2013 and step by step has built-up several fields of business activities.

Some famous partners of Roeders include:

BUSINESS AREAS

– Machines for Milling and Grinding and Automation renown for highest precision and efficiency

– Mechanical Precision Machining equipped with highly precise machines for milling, grinding and turning

– Sheet Metal Production with newest laser cutting and bending machines as well as a paint shop

– PET Blow Mould Manufacturing on Roeders’ own High Speed Cutting machines

– Quality Assurance on several state of the art Zeiss coordinate measuring machines

FEATURED PRODUCTS

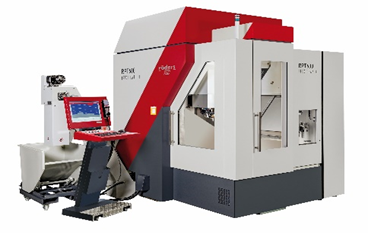

Roeders HSC Milling machine

Salient features

- Construction Materials: HSC Roeders milling machine is made from high quality materials, ensuring durability and absolute accuracy during the processing process.

- High Precision: Designed to meet the most demanding requirements, HSC Roeders milling machines enable machining with micron precision, ensuring the final product meets the highest standards.

- High-Speed Cutting: HSC (High-Speed Cutting) technology helps Roeders milling machines operate at high speed, reducing machining time and increasing production efficiency.

Industrial applications

- Mold Industry: HSC Roeders milling machines are ideal for the production of complex molds with high precision requirements.

- Automotive Industry: Used to process automotive parts with high precision and quality, ensuring the smooth and safe operation of vehicles.

- Aviation Industry: With the ability to process difficult materials and require high precision, HSC Roeders milling machines are the top choice in the aviation industry.

- Precision Machine Manufacturing: Widely used in manufacturing precision machinery parts, ensuring durability and high performance.

Design and Technology

- Modern Design: HSC Roeders milling machine has a modern design, optimizing working space and easy to operate.

- State-of-the-art Technology: Equipped with advanced technologies such as advanced CNC control system, automatic cooling and lubrication system, helping to increase machine life and ensure high performance.

- Friendly Interface: User-friendly control interface, making it easy to operate and monitor the machining process.

Benefits of Using HSC Roeders Milling Machine

- Increased Productivity: Reduce machining time thanks to high speed and absolute precision.

- High Product Quality: Ensure the final product has the best quality, meeting all strict customer requirements.

- Cost Savings: Minimize maintenance costs and increase machine life thanks to advanced design and technology.

HSC Roeders milling machines are the perfect choice for businesses that need to process parts with high precision and strict quality requirements. With outstanding features and benefits, Roeders affirms its leading position in the precision mechanical processing industry.

Roeders Grinding machines

Salient features

- Construction Materials: Roeders grinder is made from high-quality materials, ensuring durability and high performance during use.

- Absolute Precision: With an advanced design, Roeders grinding machines allow machining with extremely high precision, meeting all strict quality requirements.

- High Grinding Speed: Advanced technology allows Roeders grinders to operate at high speeds, increasing production efficiency and reducing machining time.

Industrial Applications

- Mold Industry: Roeders grinding machine is the ideal choice for producing and finishing complex molds with high precision requirements.

- Automotive Industry: Used for grinding automotive parts, ensuring smooth surfaces and absolute precision, contributing to vehicle safety and performance.

- Aviation Industry: With the ability to accurately grind difficult materials, Roeders grinding machines meet all strict requirements in the aviation industry.

- Precision Machine Manufacturing: Roeders grinding machines are widely used in manufacturing machine parts with high precision, ensuring product performance and longevity.

Design and Technology

- Modern Design: Roeders grinder has a modern design, easy to operate and maintain, optimizing working space.

- State-of-the-art Technology: Equipped with advanced technologies such as CNC control system, automatic cooling and lubrication system, helping to increase machine life and ensure high performance.

- Friendly Interface: User-friendly control interface, making it easy to operate and monitor the grinding process.

Benefits of Using Roeders Grinder

- Increased Productivity: Reduce machining time thanks to high grinding speed and absolute precision.

- High Product Quality: Ensures the final product surface is smooth and of the best quality.

- Cost Savings: Minimize maintenance costs and increase machine life thanks to advanced design and technology.

- Roeders grinding machine is the perfect choice for businesses that need to process parts with high precision and strict quality requirements. With outstanding features and benefits, Roeders affirms its leading position in the precision mechanical processing industry.

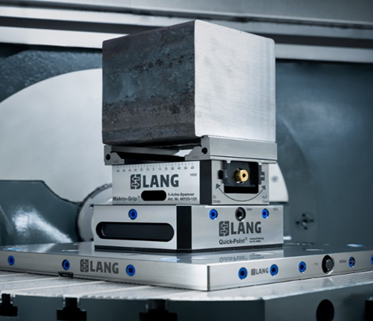

Work-holding and machine tool automation

Roeders specializes in providing advanced solutions in the field of clamping tools and machine tool automation, supporting mechanical processing companies to improve production processes, increase efficiency and optimize capacity. manufacture.

Future Solutions

- Optimize Production Process: With advanced clamping and automation systems, Roeders helps businesses simplify production processes, thereby saving time and costs.

- More Efficient Production: Thanks to automation solutions, businesses can increase production efficiency, minimize downtime and increase product consistency.

Maximize Production Capacity

- Efficient Use of Resources: Automation systems help optimize the use of machinery and labor, ensuring that resources are used in the most efficient manner.

- Improve Product Quality: Automation helps reduce errors and enhance product quality, meeting strict market requirements.

With Roeders’ machine tool automation and clamping solutions, mechanical processing businesses will have the opportunity to increase production efficiency, improve product quality and optimize production capacity. . Roeders is committed to providing the most advanced and effective solutions, helping businesses achieve outstanding success in the industry.

CONTACT INFORMATION

Booth 48– VIMF Binh Duong 2024

Tel: +84 898 788 040 – Ms Huong Giang

Website: www.omg-expo.com

Email: giang@vimf.vn

EN

EN VI

VI