INTRODUCTION

FerRobotics is the global leader in the development and distribution of sensitive robotic elements (for robotic material removal end-of-arm tooling / surface finishing end-of-arm tools / end-effectors) that equip an industrial robot or cobot with contact intelligence and constant contact force (real force control) for productivity, efficiency and safety.

We give robots feeling with our patented Active Compliant Technology. And thus ensure more efficient, finer and more valuable production results.

Our products close automation gaps seamlessly and are trendsetters in flexible automation in the automotive, aerospace and general industries on the international market. Our experts will happily show you solutions for your applications (robotic grinding, sanding, polishing, deburring, taping, …) or other requirements.

BUSINESS AREAS

Automotive, Aerospace and General Industries

(High-tech end-effectors for sensitive robotic grinding, sanding, polishing, taping, and more)

FEATURED PRODUCTS

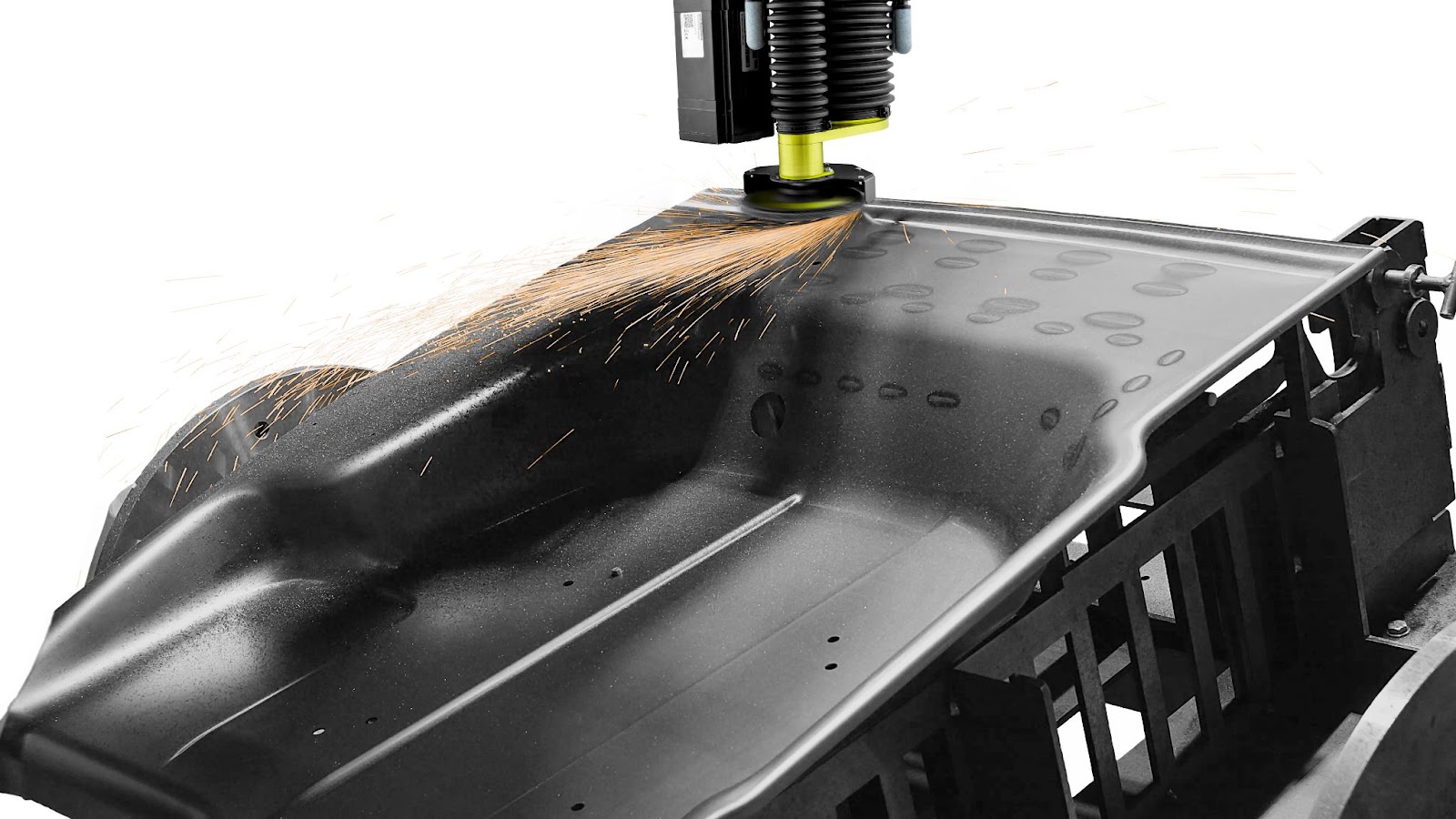

AAK 501 Active Angular Kit

As an integrated grinding solution for weld seam leveling, the Active Angular Kit guarantees a significant increase in productivity. The precisely-matched system package combines the Active Compliant Technology with a robot-compatible angle grinder. FerRobotics integrated complete solution automates the industrial robotic grinding process with individual control of all process parameters: speed of rotation, constant contact force in any orientation and best possible robot feed rate.

That means an AAK offers the highest process quality from one source with a system design that is compact and simple. In fact this enormously durable grinder is designed for industrial use and delivers twice the output of standard devices and creates beautifully finished parts, 24 hours a day, 7 days a week.

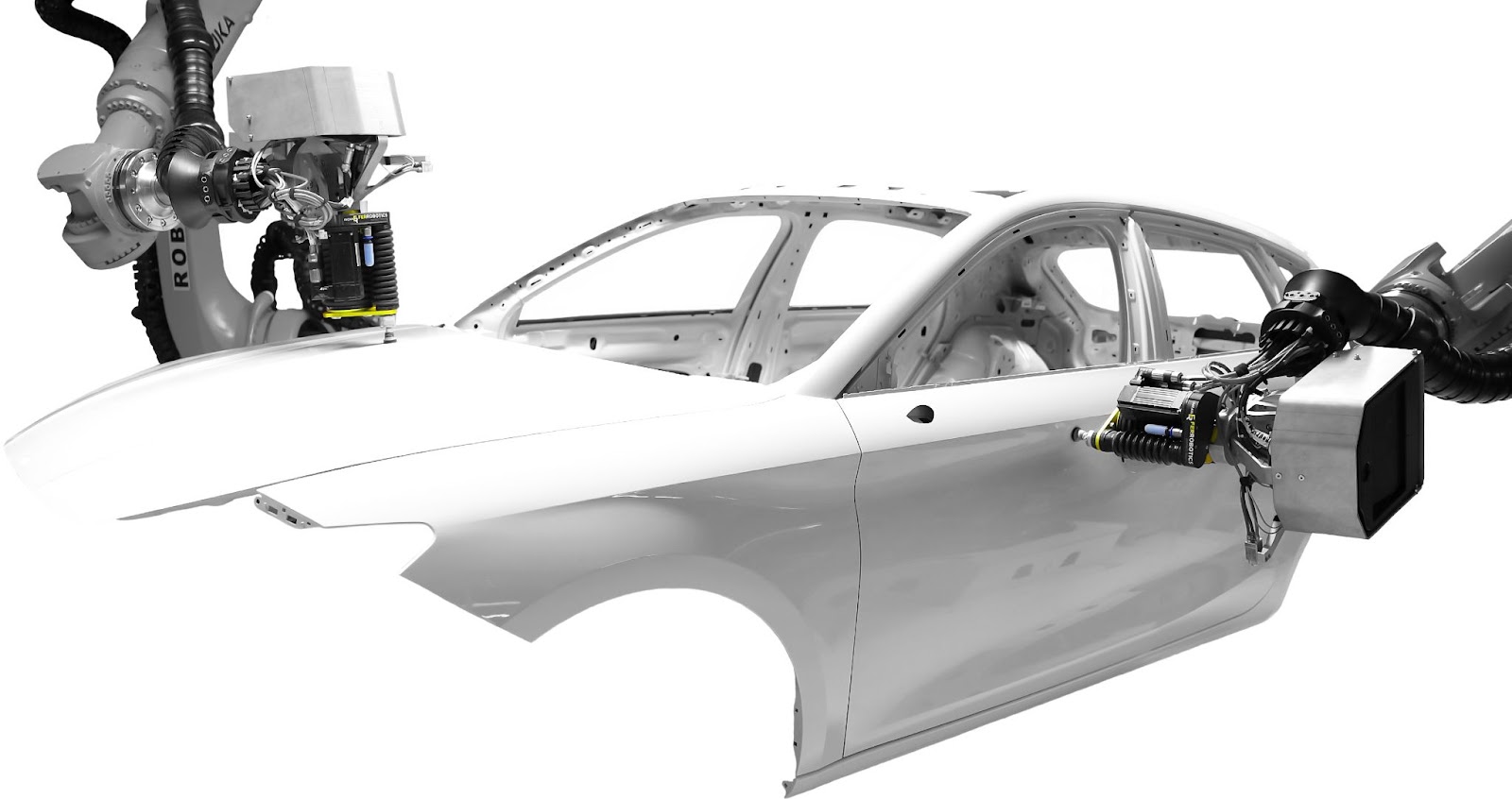

AOK 401 Active Orbital Kit

The Active Orbital Kit is an intelligent system package, which combines the Active Compliant Technology with a specially developed electrical orbital sander/polisher driven by a fully integrated servomotor. This complete solution automates the industrial surface finishing process (for delicate tasks like paint repair) with individual control of all process parameters: speed of rotation, constant contact force in any orientation and best possible robot feed rate.

Fact is: the AOK Family offers the highest process quality from one source with 100% real-time process control and a system design that is compact and simple. The enormously durable end-of-arm-tool is designed for industrial use and delivers twice the power output of standard devices for a perfect surface treatment, 24 hours a day, 7 days a week.

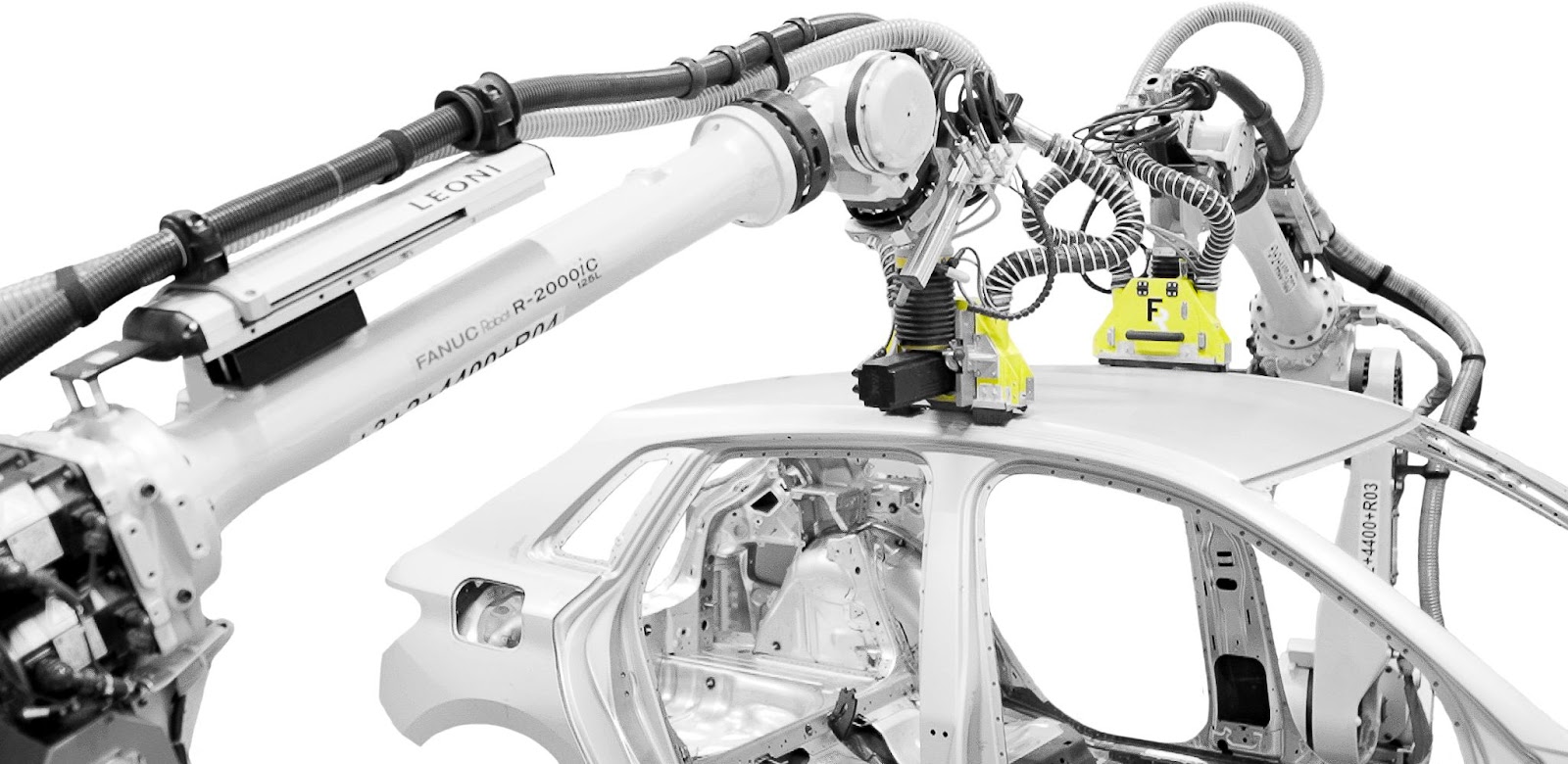

ASK 201 Active Sensitive Kit

The Active Sensitive Kit comprises a complete package as robot add-on going above and beyond the pure product. This comfortable solution enables to use the ACT potential on a sophisticated individual level.

The ASK was developed as a special convenient solution to enable the post-production processes for welded seams, weld spatters and powder deposits to be optimized. There are no additional, manual process steps required. It goes without saying that this technology can also be seamlessly integrated into existing structures.

CONTACT INFORMATION

Booth 314– VIMF Binh Duong 2024

Tel: +84 898 788 040 – Ms Huong Giang

Website: www.omg-expo.com

Email: giang@vimf.vn

EN

EN VI

VI